Ethylene vinyl acetate (EVA) is a copolymer material and is in the category of rubbers (both copolymer and rubber are defined). This rubber is obtained by the copolymerization reaction of two monomers of ethylene and vinyl acetate. If two monomers are used, its type is different and these changes change the physical and mechanical properties of ethylene vinyl acetate and can be changed depending on the type of need. This copolymer has both the crystalline properties of polyethylene and acts like an amorphous material. Therefore, with increasing the weight percentage of vinyl acetate, the transparency as well as the flexibility of the copolymer increases.

The broad formula of ethylene vinyl acetate is:

CH3 – CO – CH = CH2

Vinyl Acetate Monomer VAM (Vinyl Acetate Monomer) is used to produce polyvinyl acetate polymer and various homopolymers and copolymers, which are produced by using vinyl acetate monomer and other monomers such as acrylic and methacrylic acids, total monomeride and monomer. The vinyl acetate monomer, known as acetylene ether acetic acid or vinyl acetate acetic acid, is a colorless liquid with a pleasant but burning odor, the formula of which is CH3-COOCH3. It ignites very quickly and reacts with acids, bases and oxidants.

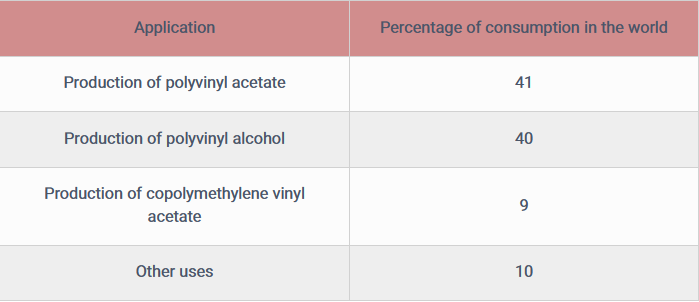

Among the uses of VAM monomer are copolymers of vinyl acetate, polyvinyl acetate and polyvinyl alcohol, the percentage of global consumption of which is given in Table (1-2). Ethylene vinyl acetate copolymer is produced by emulsion method in medium pressure using vinyl acetate and ethylene monomer. A significant percentage of EVA is vinyl acetate (over 75%). This material is used in the production of adhesives and sealants.

One of the important features of EVA product is the density percentage of vinyl acetate and also the melting coefficient, which two cases, namely the percentage of vinyl acetate and the melting coefficient are effective in the applications of this material. For example, bags or heavy containers generally need vinyl acetate of about 10% by weight or less, and also their melting point should be or less. For films, the need for vinyl acetate is about 27% by weight or less, with a melting point of about. For materials used as adhesives and modifiers, the need for vinyl acetate is about 15-30% by weight and melting point is more than.

Density:

EVA density increases from 929% to about 974% gr / cm3 with increasing percentage of vinyl acetate from 5wt% to 40wt%. Increasing the density of the copolymer reduces the melting coefficient. For example, the melting coefficient of a copolymer containing 20 wt% of vinyl acetate rises from less than to above and its density decreases from a value above 940% gr / cm3 to less than 3940 gr / cm.

Molecular weight and its distribution (lateral branches):

Increasing the molecular weight of EVA reduces its melting index. The molecular weight distribution of EVA produced at the same temperature and pressure increases with increasing percentage of vinyl acetate in the polymer mixture. The type and number of short side chains are highly dependent on the polymerization conditions as well as the chain transfer factor. For example, when propylene is used as a chain transfer agent, side chains often contain methyl groups. Increasing the chain of short branches reduces the crystallinity of the copolymer. Long chain chains (alcohol chains with more than six carbon atoms) usually distribute a wide molecular weight in EVA. The degree of long branch chains can be very important in some applications because of its effect on the flow characteristics at the melting point of the copolymer.

Mechanical properties:

Increasing the percentage of vinyl acetate in EVA copolymer can increase the elongation, crack resistance to environmental factors, crack resistance to bending, impact resistance, shear force and tensile strength of the film. Improving the crack resistance of environmental factors, impact resistance and flexibility, especially at low temperatures, can be important for EVA copolymers used at low temperatures. In general, increasing the EVA melting coefficient reduces elongation, crack resistance of environmental factors, impact resistance and shear force.

Temperature properties:

Low sealing temperature and low temperature brittleness point are very important for EVA properties and make it more useful for applications such as warehouses.

Hardness:

Increasing the percentage of vinyl acetate or melting coefficient reduces the hardness of EVA.

Moisture permeability:

Moisture permeability in EVA film increases with increasing percentage of vinyl acetate. This increase is effective when the film is thinner. Melting coefficient has only a negligible effect on moisture permeability.

Film grades:

Most film grades of copolymer have a vinyl acetate content of about 15 wt% or less. Combining 2wt% or less of vinyl acetate with the copolymer, without affecting the hardness, helps the clarity, clarity and order of the film.

Injection molding grades:

For injection molding, EVA copolymer with a percentage of vinyl acetate between 6% wt and 30% wt is used. EVA copolymer with vinyl acetate content between 9wt and 45wt% is used for grades of adhesives, extrusion, coagulation, coating, lamination and high melting.

Adhesive, extrusion, coating, lamination:

EVAs containing 9 to 45% by weight of vinyl acetate are used commercially in adhesives (including heat melt, gold base and pressure sensitive). Copolymers containing more vinyl acetate are usually recommended for use in cases where strong bonds are required. For hot melt adhesives, a copolymer containing 28% by weight of vinyl acetate is used because of its compatibility with crystalline waxes and viscous resins. Table (2-2) presents the properties of selected commercial adhesives.